PROTOTYPING

What all we can do & deliver: Rapid Prototyping – FDM, SLA, SLS, Hand-made fabricated prototype & mock-up, clay models, architectural models, spray painting, product assembly for design evaluation & testing. Customized solutions as per need and expectations of the client team. Mostly we interact with engineering team for a complete understanding of the requirements, we check the given 3D models when it is going for 3D printing and read the drawings when a functional prototype is needed. We try to match the colour as per PANTONE shades give to have a close match in look of the product with spray painting

THE SOLUTIONS

WE OFFER

HANDMADE MODELS

When there is a need of a very basic physical model for visual or size impression check – we can make basic handmade models in different materials like paper/cardboards, clay, thermocol, PUF, wood, acrylic sheets, etc. We can also make detailed true scale models made of metal sheets & pipes, woods, and plastic sheets for a functional check in real usage of applications or installations. We have 4 Axis CNC routers in-house to make wooden parts and models – complex profiles can be made in wood with the help of this CNC router. Completely customized solution as per the need.

RAPID PROTOTYPING

We have in-house FDM machines and partnered with multiple setups in Mumbai & Kolkata who are having all high-end precision 3D printing systems. Our team is very much aware of all updated technologies and application areas. We have sound knowledge of engineering designs or product design, parts configurations, and assembly. We are capable of offering solutions for prototyping with less number of iterations to get the final working perfect pieces as we do check the parts in 3D and review if there is any issue – inform & suggest client about the problem areas and ways to improve. Our creative and analytic minds work together even for prototyping services.

PAINTING & FINISHING

We have a shared workshop of DesignLipi & CraftLipi. We have skilled artisans who can do complete finishing of a part – surface cleaning, applying putty, water buffing and spray painting. We get colours mixed by professional setup as per client requirements referred by PANTONE shade cards and try to match the colours as much possible. We use different techniques to get surface texture difference too. This may be a but JUGGAD but it works!

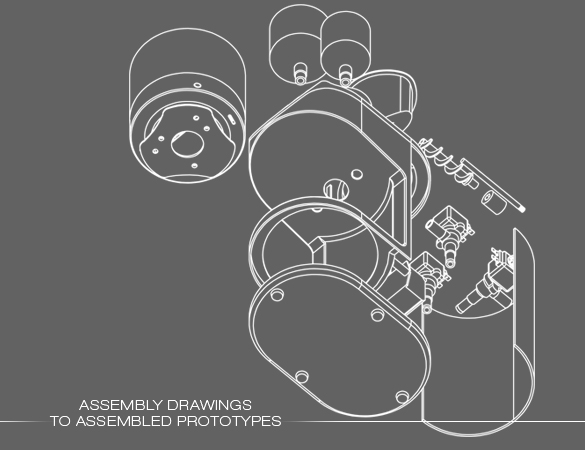

PRODUCT ASSEMBLY

We have a team who can offer product assembly service where parts can be made of 3D printed materials, wood, metal pates & tubes along with electrical, electromechanical, and electronic materials given by the client. This is an extended service of model making and prototyping – when client needs semi-functional or fully functional prototypes for market or functional testing.

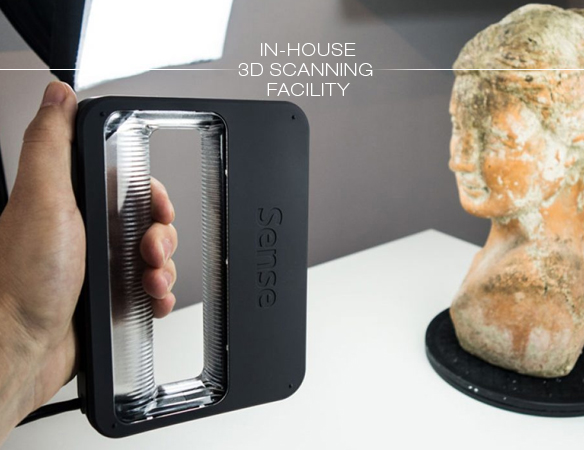

3D SCANNING

We have handheld 3D scanning (Sense 3D of 3D systems) device inhouse which can do the 3D scanning of good size objects in true scale, and we do use that to get basic details to use that for making final engineering 3D models of the object with right dimensions, proportions of elements or profile details and with different angles or projections. We will be adding a high-end precision 3D scanner very soon.

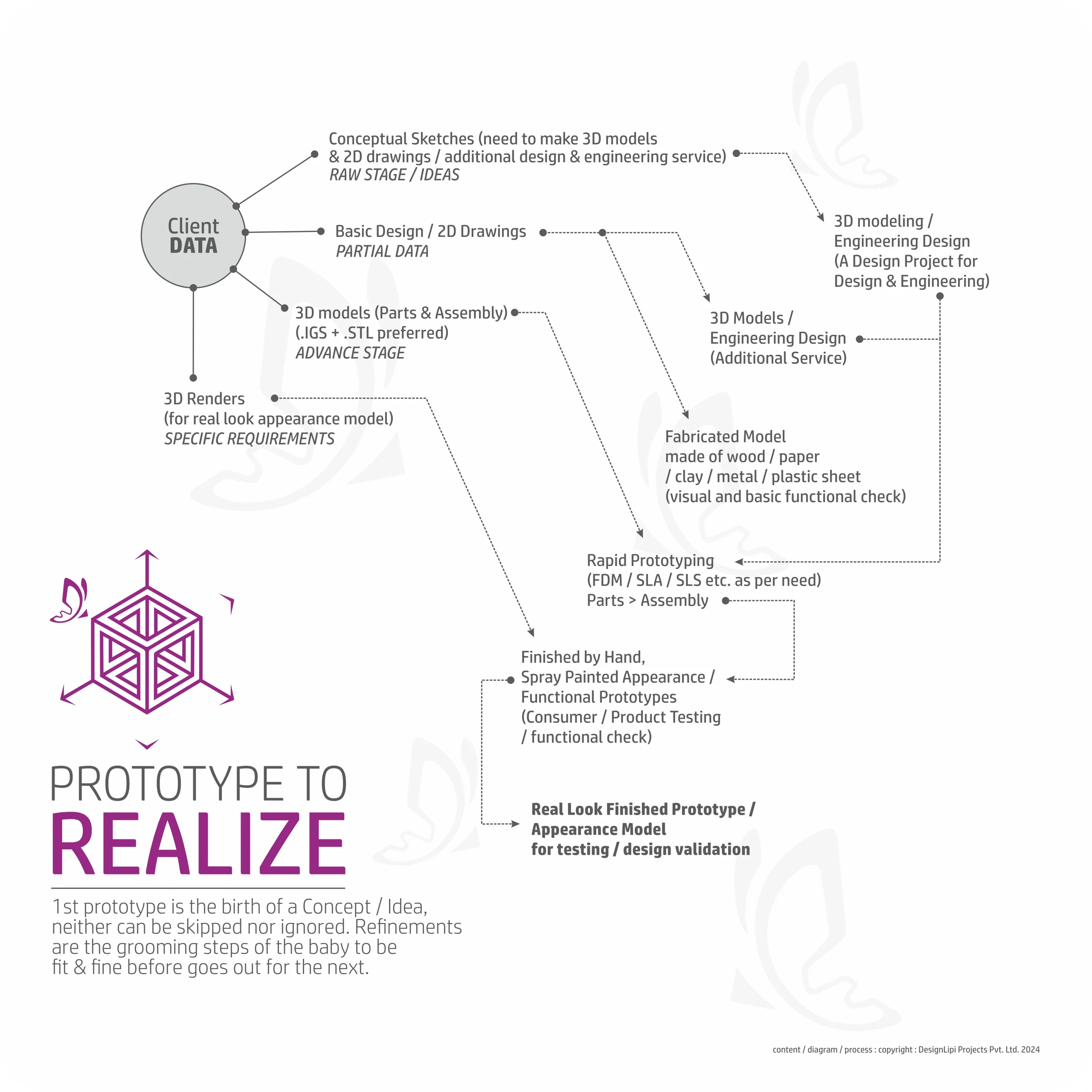

PROTOTYPING PROCESS