PRODUCT DESIGN

Whatever small product it may be, designing a product and taking it to manufacturing considering all aspects of product lifecycle & touchpoints – functionality, usability, manufacturability, cost-effectiveness, assembly, and even transport friendliness – is not at all an easy task. We are a bit experienced to consider every aspect of those critical parameters to make the product successful one – launched on the ground with happy faces in businesses and users.

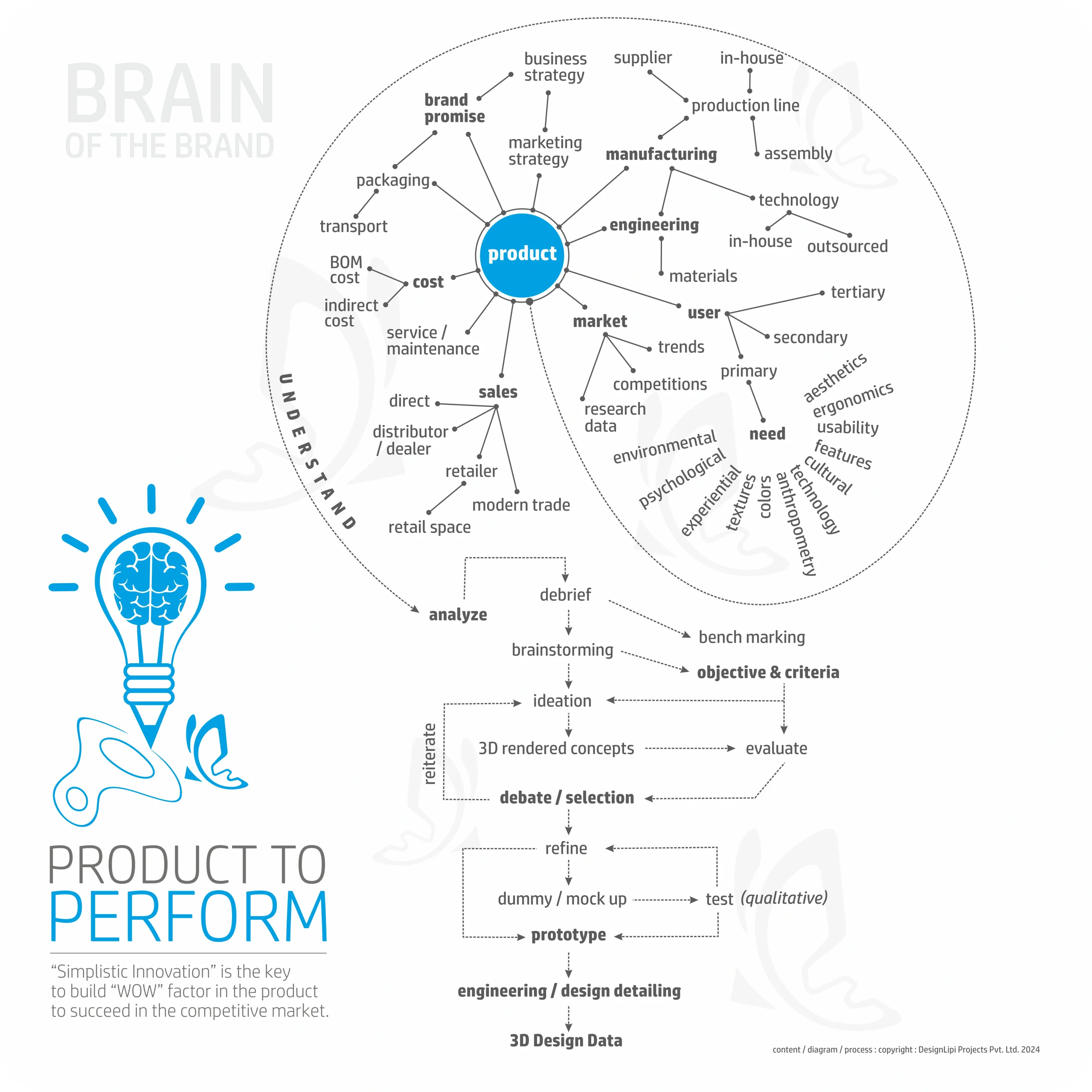

Our Approach

Understand With Empathy

Understanding the product, business, user, environment, market, etc. – the complete product life cycle, as well as each touch points, is very important for us to have good knowledge about the context where we as designers start with. We visualize and build scenarios with product usage environment and usage with user stories. Research is mostly on the ground, but we also go by our experiences too from the same or other domains of product categories.

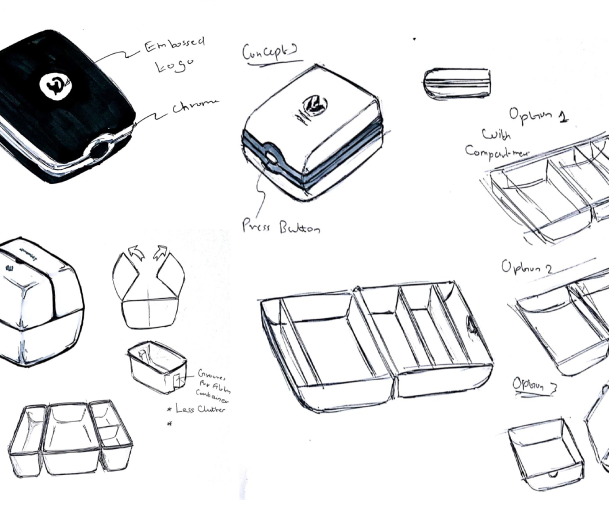

Scribbled Ideas

From our Mind or Brain where imagination & visualization starts Hand – scribbles & doodles are the starting phase where ideas take shapes through pencils on paper. We never go to the computer straightway as that compromises our thinking process because of computer constraints or software knowledge. Sometimes we do make clay or paper models to give a shape – to hold it or feel it. We do take the help of Mood Boards for getting ideas on shapes whenever needed for “Experiential” Products. This phase is experimental & experiential for us which we designers enjoy most as it helps to shape our thinking process bringing clarity to the ideas we are thinking.

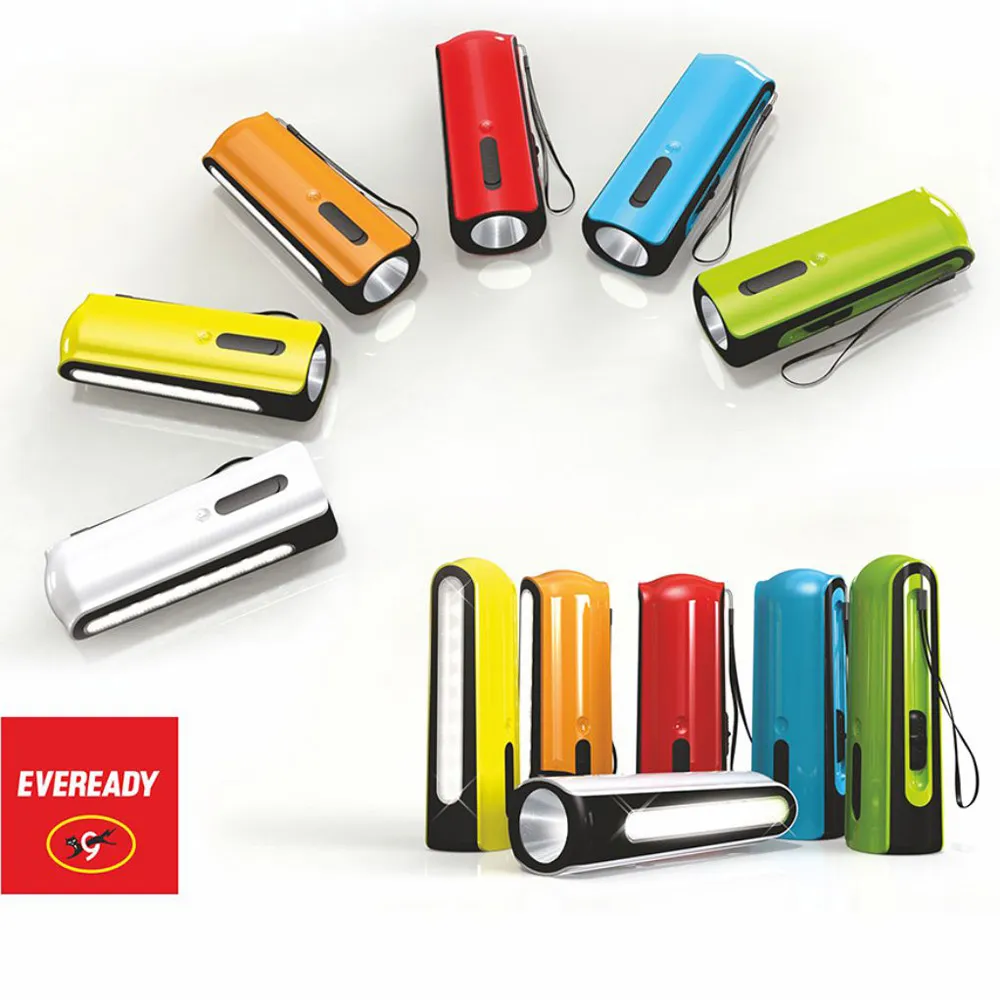

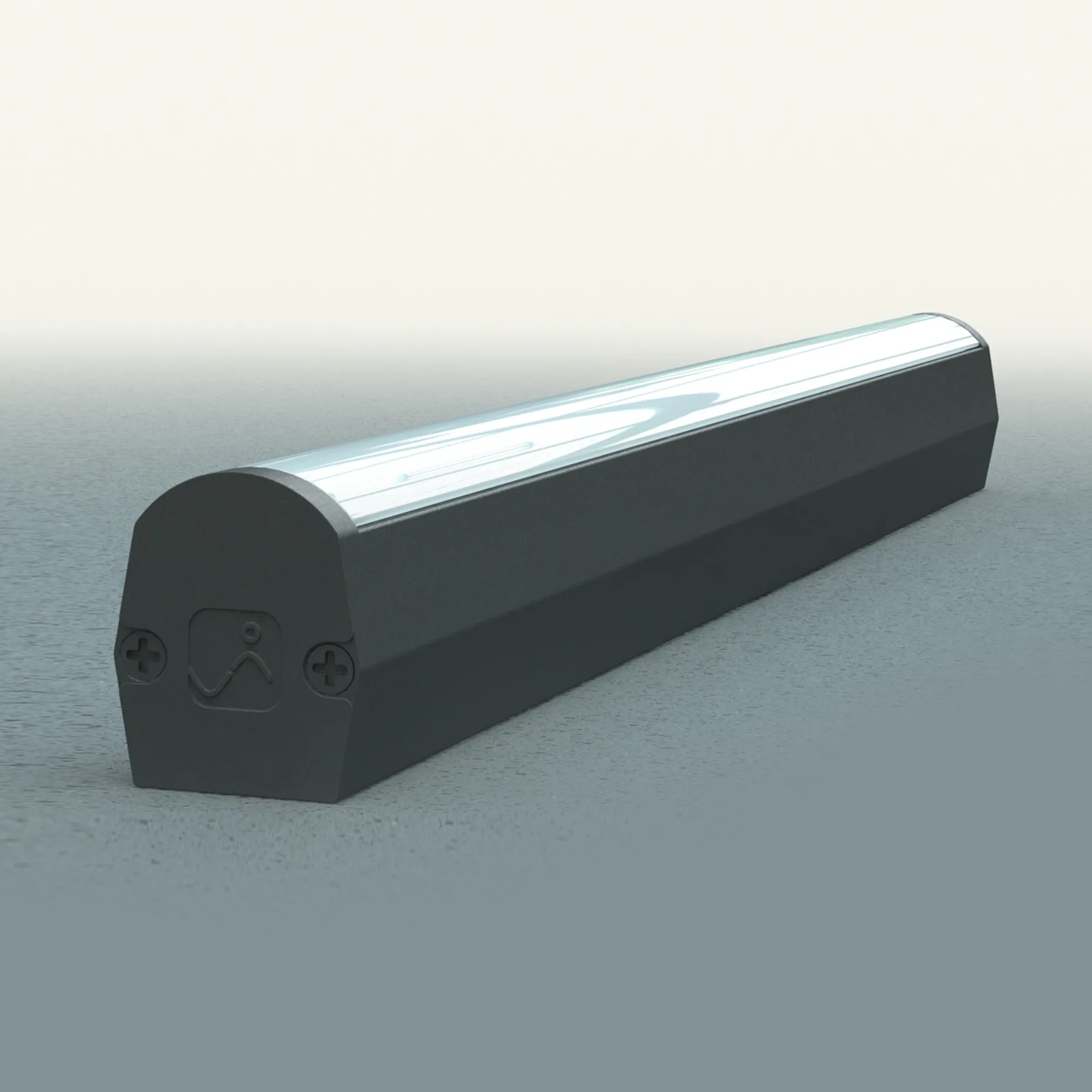

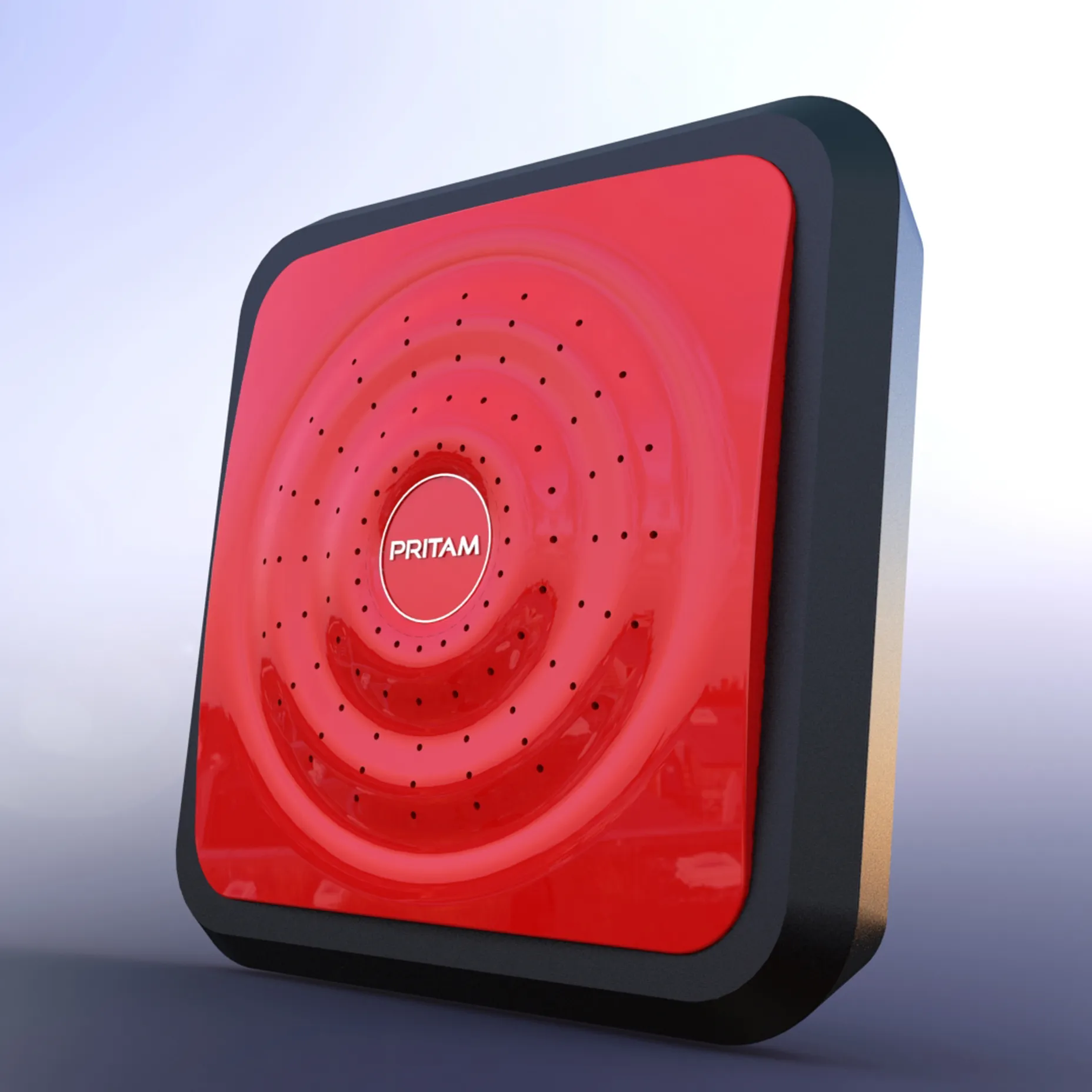

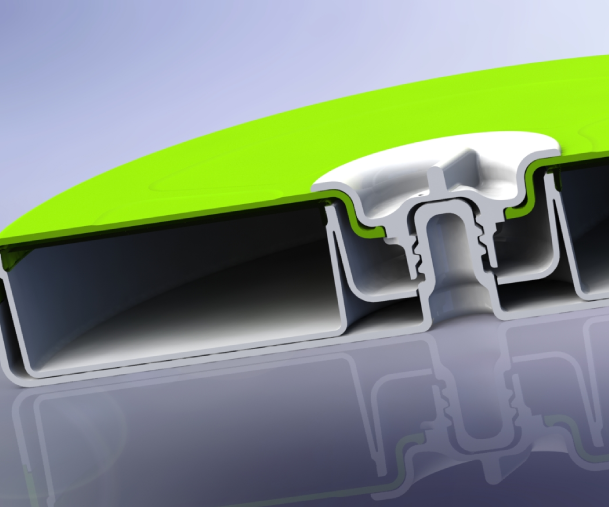

Cool Concepts In 3d

Those scribbles or doodles are being filtered and shortlisted for 3D modeling on a computer – the CONCEPTS. Concepts are limited in numbers, but the best 3 ideas are being converted into 3D and presented in photorealistic renders for visualization by all stakeholders – from management, and marketing to R&D, and manufacturing. These renders can also be used for initial level of concept evaluation by User and Channel Partners. While we make 3D – we do have some clarity on product components/parts and size impressions which are vital for concept evaluation.

Engineering Matters

Concepts are not great just by looking at 3D renders in digitized forms. These must be made on the manufacturing floor and assembled with fit & finish as desired. We go for complete engineering design of the products with parts and components fitted inside. Materials are also being evaluated by checking the weight of the parts. Assembly checks are done in 3D. We share these 3D with the tooling & manufacturing team for evaluation. The final Engineering model gets ready for prototyping: rapid prototypes and fabrication as per need.

Prototyping

This is a very much exciting moment when we all see the product physically and hold to experience for the first time. We can check everything about the product – form & function, fit & finish. We do make rapid prototypes or hybrid prototypes combining different materials or fabrication processes. We have an in-house spray painting facility and people to give it a final look if it is intended for consumer/market testing or evaluation.

Handholding

We do support SME and MSME when they don’t have in-house design teams for getting the product made and support till the pilot lot – with multiple interactions with tool makers, resolving issues if any arises, T1, T2, T3 sample check, and giving reports, check on finishes and assembly, etc. We also act as an extended team of corporate R&D to support the process of NPD.

Products in Reality

The product gets Launched. We celebrate. This is the happiest moment for us as designers to see the product in the Market with the happy faces of the Client and Consumer. We are a small team of passionate people full of dedication – we do work hard day & night to make things happen with a positive mentality and attitude.

PRODUCT DESIGN PROCESS